4 Valuable Lessons from the Partially Unsuccessful First Flight of SLV-3

India's first satellite launch vehicle SLV-3 had a partially unsuccessful first flight. Learn 4 valuable lessons from the journey of this SLV-3 E1 Mission.

India's first satellite launching rocket, the Satellite Launch Vehicle SLV-3 took off for the first time on 10th August 1979. The launch vehicle was unable to put the payload into orbit. It was still a technological feat nonetheless, thirty-six out of the forty-four major subsystems had performed satisfactorily for the first flight of SLV-3. Let us look at the various lessons learnt in this journey of ISRO.

SLV-3 Rocket | India's First Launch Vehicle

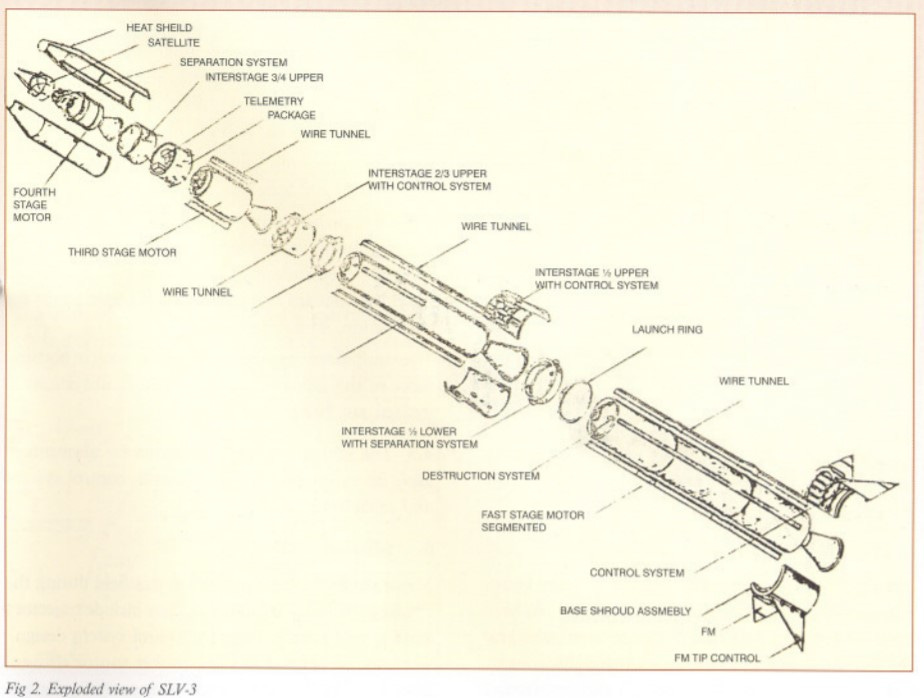

Specifications

LEO Payload: 40 kg to 400 km Orbit

Lift-off Thrust: 454.93 kN

Total Mass: 17,610 kg

Core Diameter: 1.0 m

Total Length: 24.0 m

Horizontal Integration

Primary Objectives of SLV-3 E1 Mission

Realize the SLV-3 launch vehicle system ready for flight after qualification and acceptance tests of its various subsystems

Flight-test the SLV-3 vehicle and to evaluate the performance of the stage motors and performance of the stage control systems and all other vehicle subsystems

Realize the launch complex and ground station facilities for the launch operations

Electrostatic Discharge over Payload Fairing | A lesson in Design Engineering

We all know that the rocket payload fairings are metallic. But the Indian SLV-3's payload fairing used phenol-glass honeycomb sandwich materials. The Rohini Technology Payload (RTP) had to communicate the telemetry for the in-flight monitoring during the launch phase. This requirement had led to the decision of using the insulating material for the ascent fairing.

While the use of insulators solved the requirement issue, it brought its own—the problem of electrostatic charge build-up. There were many risks associated with charge accumulation, such as arc-overs. The solution was simple. Use several longitudinal metallic wires embedded in the fairing. But now, these wires could compromise the radio transparency of the original requirement. Therefore, they tested the system by creating a particular test setup.

The similar problem of unequal electrostatic discharge on different stages was also solved using thin connecting wires between the stages. These wires would snap when the separation between the stages increased to about a meter.

An explosion during RCS testing | A lesson in Safety Procedures

The second stage of the SLV-3 launch vehicle used a bi-propellant reaction control system (RCS). Red Fuming Nitric Acid (RFNA) and Hydrazine were the two propellants used. The combination of these fuels results in a Hypergolic Propellant, which means it ignites simultaneously as the two fuels come into contact with each other.

On 18th May 1978, the second-stage control system was ready for the first hot test. But before the test could begin, a minor leak was noticed in the RFNA line. To rectify the leaking joint, the team removed the protective garments. The hot and humid weather was the culprit behind this decision. Suddenly, the fuels burst into an explosion. Fortunately, no-one got killed, but six individuals sustained critical burns.

The incompatibility between the fibreglass tank and the internal rubber lining was identified as the cause of the leak and subsequent explosion. ISRO then decided to use a stainless steel tank for RFNA and Teflon for bladder material. Also, better protective garments with forced air cooling were made available.

Perfection is not the Key to Success | A lesson in Systems Engineering

One of the significant configuration and status reviews of SLV-3 ended with everyone understanding the importance of 'Good-Enough' rather than 'Perfect'. The review meeting started on 23rd October 1978 with participation from Prof Dhawan and Dr Brahm Prakash. Once the starting remarks ended, and the meeting went into free-for-all mode, differences rose related to time-schedules and readiness of subsystems. Every subsystem wanted more time to improve its specifications. While the overall system required systems which fulfilled the requirements, subsystem teams were so motivated, that they were trying to accomplish more. This was resulting in delays and mismatches.

Dr Brahm Prakash concluded the meeting on 24th October (yes, it took two days). He ended with a humorous story, as described by Ved Prakash Sandlas, 'Once, a professor selected two PhD students. After a couple of years, one student completed his work quickly and submitted the thesis. The other student had not even finalized his choice of problem, and had been changing his ideas continuously, prompting the professor to say, 'My friend, where would you have been if your father had waited for the last suitable girl?"

During my time at the IIT Bombay Student Satellite Team, I have also realized this critical aspect of systems engineering. We often undertake a journey to achieve the best possible. While as an overview, it seems a great idea, it leads to delays. Any system has a time when it should be designed, manufactured and deployed. If you strive to go a few extra steps, it may lead to losing these deadlines. And the competitors take over with less but good-enough products.

The Final 'Partially Unsuccessful' Launch | A lesson from the Failure

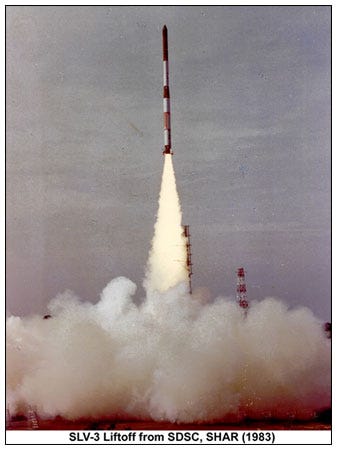

SLV-3-E-01 launched on 10th August 1979 at 0758 hours. The lift-off was flawless, followed by the perfect first stage burn. At about T+50 seconds, the second stage had taken over. The tracking radars started announcing lower range and altitude, indicating underperformance, followed by loss of telemetry signals and splash into the Bay of Bengal at T+317 seconds, about 560km south-east of SHAR. The whole excitement for the last few years ended into despair within 300 seconds. As Dr APJ Abdul Kalam described, 'It is something like a pleasant dream suddenly turning into a frightening nightmare!'

The detailed post-flight analysis identified the problem with the second-stage Reaction Control System (RCS). The RFNA had leaked and depleted before the lift-off itself. While the SLV-3 was still on the launchpad, a series of warm-up pulses successfully opened the solenoid valve. But the valve, designed to close after the pulses, did not close.

The reason for the valve not closing as scheduled was to be found next. There could be two significant reasons. Contamination of the valve during the integration of the launch vehicle or an Electrical problem leading to continuous pulses rather than just for the warm-up duration. Because the battery voltage remained constant throughout the countdown, the electrical problem was ruled out

There were multiple indications as well, which had pointed to the RFNA leak. The only colour camera footage clearly showed orange-coloured fumes emanating from one of the control thrusters. There were even visible yellow spills on the floor of the launch pad. There was also a computerized hold before the lift-off indicating the reducing pressure in the gas bottles. But, this hold was quickly overridden manually, since the residual pressure was considered adequate by the concerned specialists.

The solution to the problem was simple. Put appropriate filters to block contaminant particles. For the subsequent flights, it was decided to carry out the final assembly of control system components in a clean tent, and by introducing micron-level filters in the fuel and oxidizer lines.

Though the flight failed, it was termed as a 'Partially Unsuccessful' Flight and rightly so. Thirty-six out of the forty-four significant subsystems of the SLV-3 performed satisfactorily. Also, the flight proved that all the launch complex facilities and ground stations were fully operational. And the team showed its resilience and commitment by starting work immediately for the next flight. Finally, on 18th July 1980, the SLV-3 E2 demonstrated the successful flight of the SLV-3 launch vehicle.

Also check out the article on SLV-3 second experimental flight, which was also India's First Orbit Flight.

This article was based on a chapter from the book The Leapfroggers: An Insider's Account of ISRO.